REVERSE OSMOSIS SYSTEMS

We offer two lines of seawater reverse osmosis desalination systems as well as a line of brackish water reverse osmosis desalination systems.

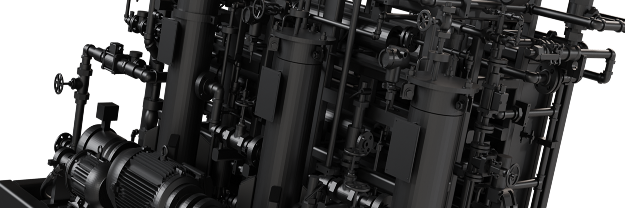

The Sterling Series

Our Marine Reverse Osmosis systems are available in fresh water production capacities ranging from 1,000 GPD to 10,000 GPD. Custom units are available upon request.

Standard features include:

- Stainless steel corrosion resistant frame

- 2205 duplex stainless steel high pressure piping

- Victaulic couplings for easy parts replacement

- 2205 duplex stainless steel ultra-quiet Danfoss pump

- 5-Micron sediment filter

- 4” x 40” high rejection seawater membranes

- Low and high pressure switches

- High pressure relief valve

- Pressure gauges: Prefilter Outlet, Pump Discharge, Concentrate, Intermediate Concentrate

- Permeate total dissolved solids (TDS) meter

- Automatic back flush

- Energy efficient design

- 60Hz electrical service (50Hz optional)

- Fiberglass pressure vessel(s), 1000 PSI

- Vertical & horizontal configurations available

The Sterling Series Seawater Reverse Osmosis Systems

| Model | Gallons Per Day | m3 | Membrane Size | No. of Membranes | Weight (lbs) | Dimensions (DxWxH) |

| STR-1 | 1,000 | 3.79 | 4″ X 40″ | 1 | 285 | 30″x33″x68″ |

| STR-2 | 2,000 | 7.57 | 4″ X 40″ | 2 | 330 | 30″x33″x68″ |

| STR-3 | 3,000 | 11.36 | 4″ X 40″ | 3 | 390 | 30″x33″x68″ |

| STR-4 | 4,000 | 15.14 | 4″ X 40″ | 4 | 440 | 30″x33″x68″ |

| STR-5 | 5,000 | 18.93 | 4″ X 40″ | 5 | 475 | 30″x33″x68″ |

| STR-6 | 6,000 | 22.71 | 4″ X 40″ | 6 | 550 | 30″x33″x68″ |

| STR-8 | 8,000 | 30.00 | 8″ X 40″ | 2 | 750 | 50″x42″x80″ |

| STR-10 | 10,000 | 37.85 | 8″ X 40″ | 3 | 850 | 50″x42″x80″ |

The Titanium Series

The Titanium Series Reverse Osmosis Systems have fresh water production capacities ranging from 16,000 GPD to 32,000 GPD. Custom units are available upon request.

Standard features:

- Danfoss High Pressure Feed Pump

- 2205 Duplex High Pressure Piping

- Low & High Pressure Switches

- 5-Micron Sediment Filter

- High Pressure Relief Valve

- Fiberglass Pressure Vessels, 1000 PSI

- 8” x 40” High Rejection Seawater Membranes

Optional components:

- Additional Pre-filtration as Required

- CIP Package (Clean In Place)

- Pre-Treatment Dosing System

- Post Treatment Dosing System

The Titanium Series Seawater Reverse Osmosis Systems

| Model | Gallons Per Day | m3 | Membrane Size | No. of Membranes | Weight (lbs) | Dimensions (DxWxH) |

| Ti-16 | 16,000 | 61 | 8″ X 40″ | 4 | 1,050 | 80″x42″x50″ |

| Ti-24 | 24,000 | 91 | 8″ X 40″ | 8 | 2,850 | 82″x54″x100″ |

| Ti-32 | 32,000 | 121 | 8″ X 40″ | 12 | 2,950 | 82″x54″x100″ |

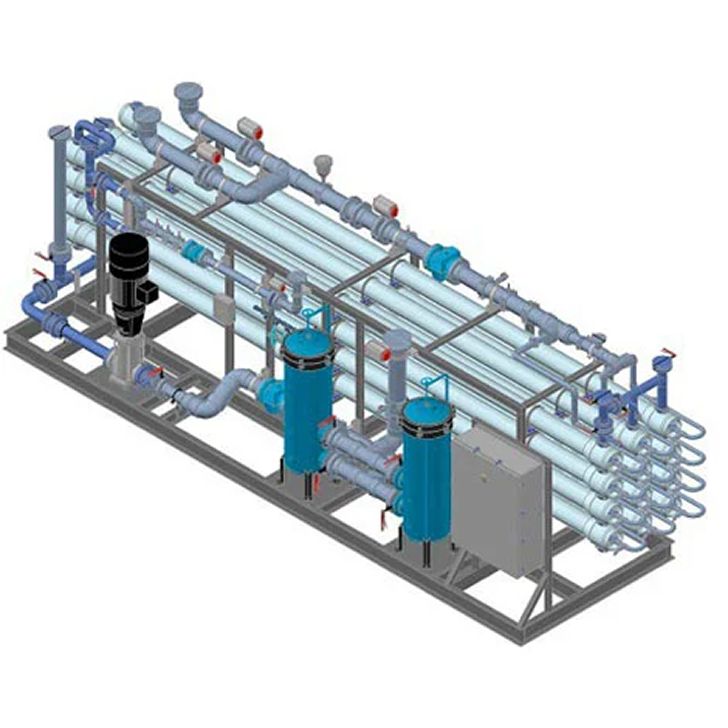

Brackish Water Reverse Osmosis Systems

Our two lines of Brackish Water Reverse Osmosis systems have water production capacities ranging from 150 GPD up to 432,000 GPD. Custom units are available upon request.

150 GPD to 22,000 GPD

Standard features:

- Powder-Coated Aluminum Frame

- Multi-Stage Centrifugal Pump

- High Rejection TFC Membranes

- PVC Pressure Vessels

- Sediment Pre-Filter

- Pump Throttle Valve

- Inlet Solenoid Valve

- Concentrate Control Valve

- Concentrate Pressure Gauge

- 110V/1Ph/60Hz

Optional components:

- Control Package

- 304 SS Pressure Vessels (300 psi)

- Automatic Fast Flush

- Differential Pre-Filter Pressure Gauges (In/Out)

- Digital TDS Monitor/Controller

- 50 Hz Motor

- Cold Water Membranes

30,000 GPD to 432,000 GPD

Standard features:

- Powder-Coated CS Frame

- 316SS High Pressure Pump

- High Rejection TFC Membranes

- Pressure Vessel – FRP Construction

- 316L SS Cartridge Filter Housing

- 316L SS High Pressure Piping

- Control Panel

- PVC SCH 80 Low Pressure Piping

- Flow Meter

- Conductivity Meter

Optional components:

- Pretreatment (MMF)

- PLC AB Control Panel

- Pre-Treatment Dosing System

- Post Treatment Dosing System

- 50 Hz Motor

- Mag Flow Meter

- VFD

- Standby Cartridge Filter, 316L SS

FAQs

Water created by an RO system will have a lower ph (acidic) due to carbon dioxide dissolved in the product water. The water also has small amounts of chlorides (salts) in the water. This combination make the water more aggressive to certain materials.

The main objective is to avoid using materials that are subject to corrosion. One option is to use Schedule 80 PVC piping & fittings. A second option is to use 90/10 Cu/Ni piping with bronze fittings. A third option is to use 316 stainless steel piping and fittings.

Install a water neutralising unit (mineraliser) at the RO unit. This would add minerals to the product water that will make the ph neutral and reduce the aggressiveness of the water and less likely to corrode piping.

The permeate discharge can overcome a 25 psig or 60 ft of head back pressure. A check valve should be provided in the discharge line unless the discharge is to atmospheric pressure.

The brine concentrate discharge can overcome a 25 psig or 60 ft of head back pressure and a check valve should be provided in the discharge line unless the discharge is to atmospheric pressure.

The feed water is to be supplied to the watermaker at a minimum pressure of 30 psig or 70 ft of head. If suitable pressure is not available, a feed water booster pump is recommended.

We recommend an 80-120 mesh duplex strainer to filter water from the sea chest then a multi-media filter and a 5-micron cartridge filter.

Parts & Service

Fairbanks Morse Defense offers an extensive portfolio of services to optimise performance, ensure reliability, and extend the life of your fleet – from the day its commissioned and for the many years that follow. Learn more about what our custom solutions can do for you.

Commercial Solutions

In addition to the defence industry, Fairbanks Morse Defense also works with the commercial industry. Our commercial customers can include municipal and nuclear power plants, hospitals, universities, and international stationary power applications.

Ready to get started?

Contact us today to request a quote or get more information on any of our solutions and services.