Innovative Davit Technology

Our core philosophy revolves around a collaborative partnership, both internally and with our clients, to meticulously craft solutions that perfectly align with project requirements. We believe in the power of synergy, where established, reliable technology seamlessly integrates with cutting-edge innovation. This approach ensures that we don’t just implement solutions but rather engineer tailored systems that deliver optimal performance and long-term value.

Our unwavering commitment to embracing innovative technologies distinguishes us as pioneers in the maritime and shipping industry. We actively seek out and evaluate emerging technologies, possessing the courage to implement those that offer tangible benefits and address evolving market demands. This proactive approach has solidified our position as a leader, consistently bringing groundbreaking solutions to our segment ahead of others.

Vestdavit’s advanced davit systems can be designed to work with Active Heave Compensation (AHC) for UUV operations.

This integration allows for the precise and controlled launch and recovery of UUVs at a pre-determined, fixed depth relative to the sea belt, irrespective of wave-induced vessel motion. This capability is critical for maintaining operational stability and ensuring the safe deployment and retrieval of sensitive underwater equipment, even in challenging sea conditions.

The AHC unit has a sophisticated Motion Reference Unit (MRC) system that can control up to three distinct systems simultaneously, enabling complex operations with enhanced precision. For instance, it can manage a dual-point davit configuration, ensuring synchronized movement for large or complex UUVs, while also coordinating a painter boom system for accurate positioning and stabilization during launch and recovery. This multi-system coordination significantly enhances operational efficiency and safety.

Vestdavit’s flexible hook distance technology provides operators with unmatched versatility by allowing them to adjust the davit configuration based on mission requirements.

This innovation enables seamless selection between different craft types, such as a 15.000 kg craft in a single-point configuration or a 30.000 kg craft in a dual-point setup, ensuring optimal adaptability for varying operational profiles. The system achieves this transition using advanced hydraulic cylinders, which dynamically adjust the hook distance to accommodate different load capacities. This flexibility allows naval and offshore operators to deploy a wide range of craft without requiring multiple davit systems, thereby maximizing space efficiency and operational readiness.

The entire evolution of the hook distance adjustment is fully automated and controlled by a Programmable Logic Controller (PLC), ensuring precise and safe operation. The PLC continuously regulates the system, providing real-time adjustments to maintain stability and load balance, even in challenging sea conditions. This advanced automation not only enhances safety but also minimizes operator workload, allowing for quick and efficient deployment and recovery of various craft. By integrating this innovative technology, Vestdavit reinforces its commitment to delivering adaptable and high-performance davit solutions that meet the evolving demands of maritime operations.

At the core of many Vestdavit systems is our Programmable Logic Control (PLC), a cutting-edge technology that optimizes the efficiency, safety, and precision of davit operations.

PLC serves as the central intelligence of our systems, executing pre-programmed sequences that automate key functions, reducing the need for manual intervention. By integrating PLC, Vestdavit ensures that operators can launch, recover, and manage various payloads with a high degree of accuracy and control, even in the most demanding maritime conditions. This level of automation enhances mission readiness and allows crews to focus on critical tasks while the davit system operates seamlessly. One of the primary advantages of PLC technology is its ability to help coordinate the movement of different components, preventing operational conflicts and optimizing space utilization within mission bays.

Safety is a core benefit of PLC integration, therefore by minimizing manual handling and automating critical functions, Vestdavit systems reduce the risk of human error and ensure compliance with stringent maritime safety regulations. PLC technology allows for single-operator control, enabling a single crew member to manage complex launch and recovery operations via a user-friendly remote-control interface. This capability not only enhances operational efficiency but also improves crew safety by reducing direct exposure to potentially hazardous environments. With Programmable Logic Control, Vestdavit continues to set the industry standard for reliability, precision, and innovation in maritime davit technology.

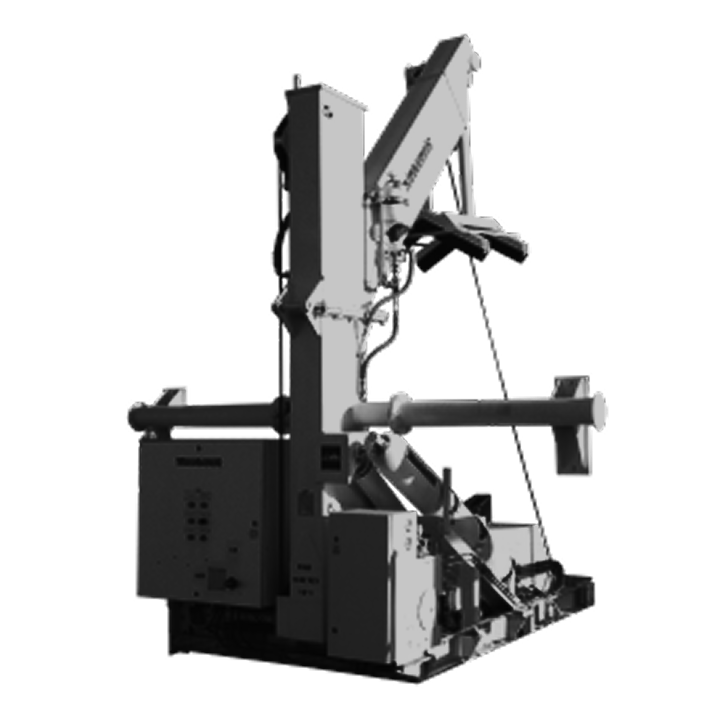

Skid-mounted davits from Vestdavit are designed as plug-and-play systems, offering ease of installation and removal to accommodate rapid role changes.

These self-contained units are pre-assembled to allow for quick positioning, and it is secured on deck with minimal effort. This design eliminates the need for complex integration processes, making it an ideal solution for vessels that require modular flexibility in their operations. Whether responding to mission-specific requirements or optimizing deck space for different payloads, operators can efficiently swap or reposition davits without extensive shipyard intervention, significantly reducing downtime and enhancing operational efficiency.

A key advantage of skid-mounted davits is that they are fully factory-built, tested, and pre-commissioned before delivery. This ensures that they arrive ready for immediate use, eliminating the risks and uncertainties associated with on-site assembly and calibration. This approach not only enhances safety and performance but also minimizes maintenance requirements, providing a cost-effective and hassle-free solution for vessels requiring adaptable boat-handling capabilities.

PIV 3.0 / PIV 4.0

The PIV 3.0 / PIV 4.0 davit is a fully self-contained “palletized” system. The safe working load of up to 4,000 kg (8,818 lbs) makes it ideal for the operation of RIBs in the 5.5 to 7.5M range.

The PIV 3.0 / PIV 4.0 reduce the installation impact to either new builds or existing vessels. The davit has integrated power pack / accumulators that are factory installed with the complete electrical system.

Integrated into the davit, the boat stowage device can be configured for most hull forms. The performance of this davit can be enhanced with all electric / electronic falls tension, shock absorber and anti-pendulum RIB docking frame.

References

Parts & Service

Fairbanks Morse Defense offers an extensive portfolio of services to optimize performance, ensure reliability, and extend the life of your fleet – from the day its commissioned and for the many years that follow. Learn more about what our custom solutions can do for you.

Commercial Solutions

In addition to the defense industry, Fairbanks Morse Defense also works with the commercial industry. Our commercial customers can include municipal and nuclear power plants, hospitals, universities, and international stationary power applications.

Ready to get started?

Contact us today to request a quote or get more information on any of our solutions and services.