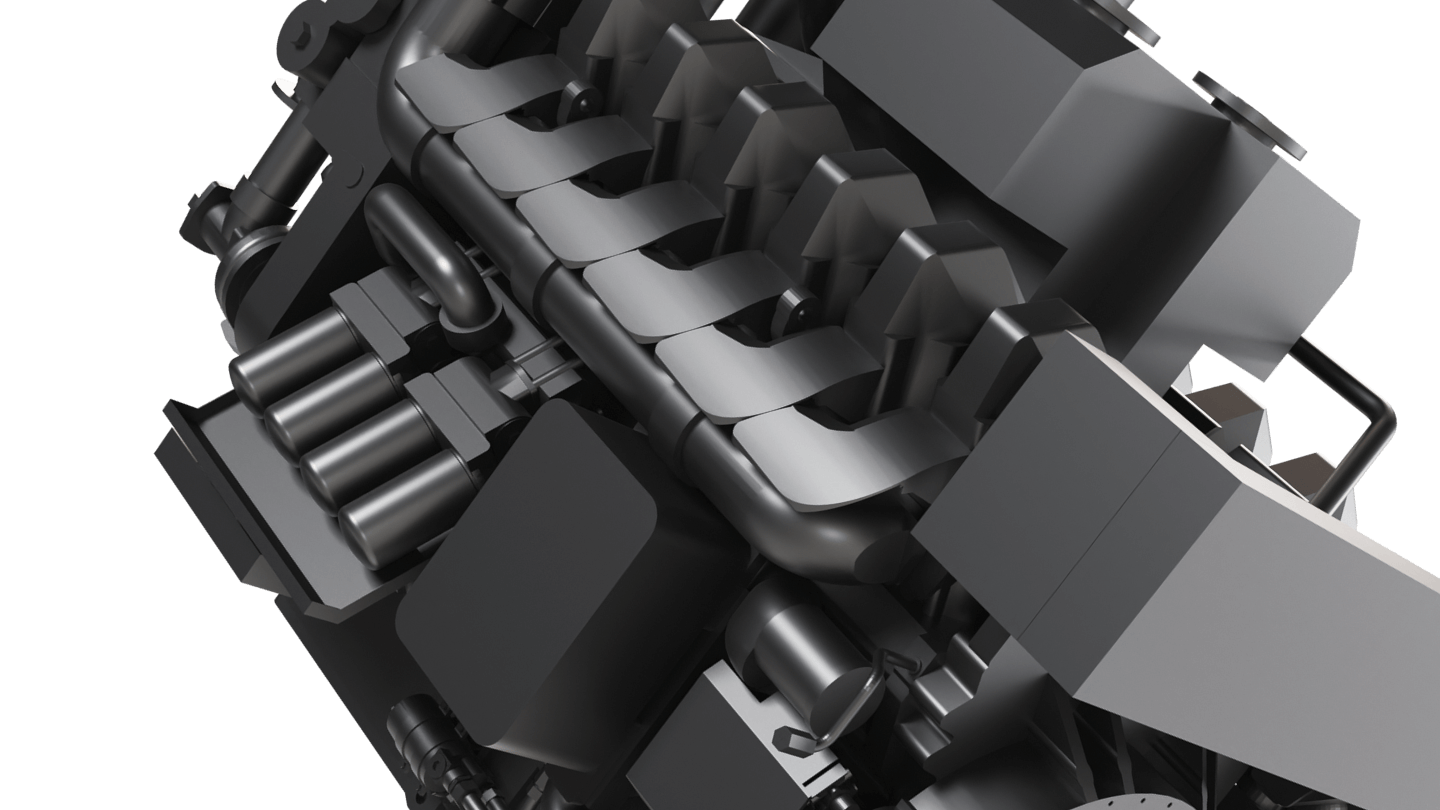

Additive Manufacturing

Advancing Innovation with Additive Manufacturing

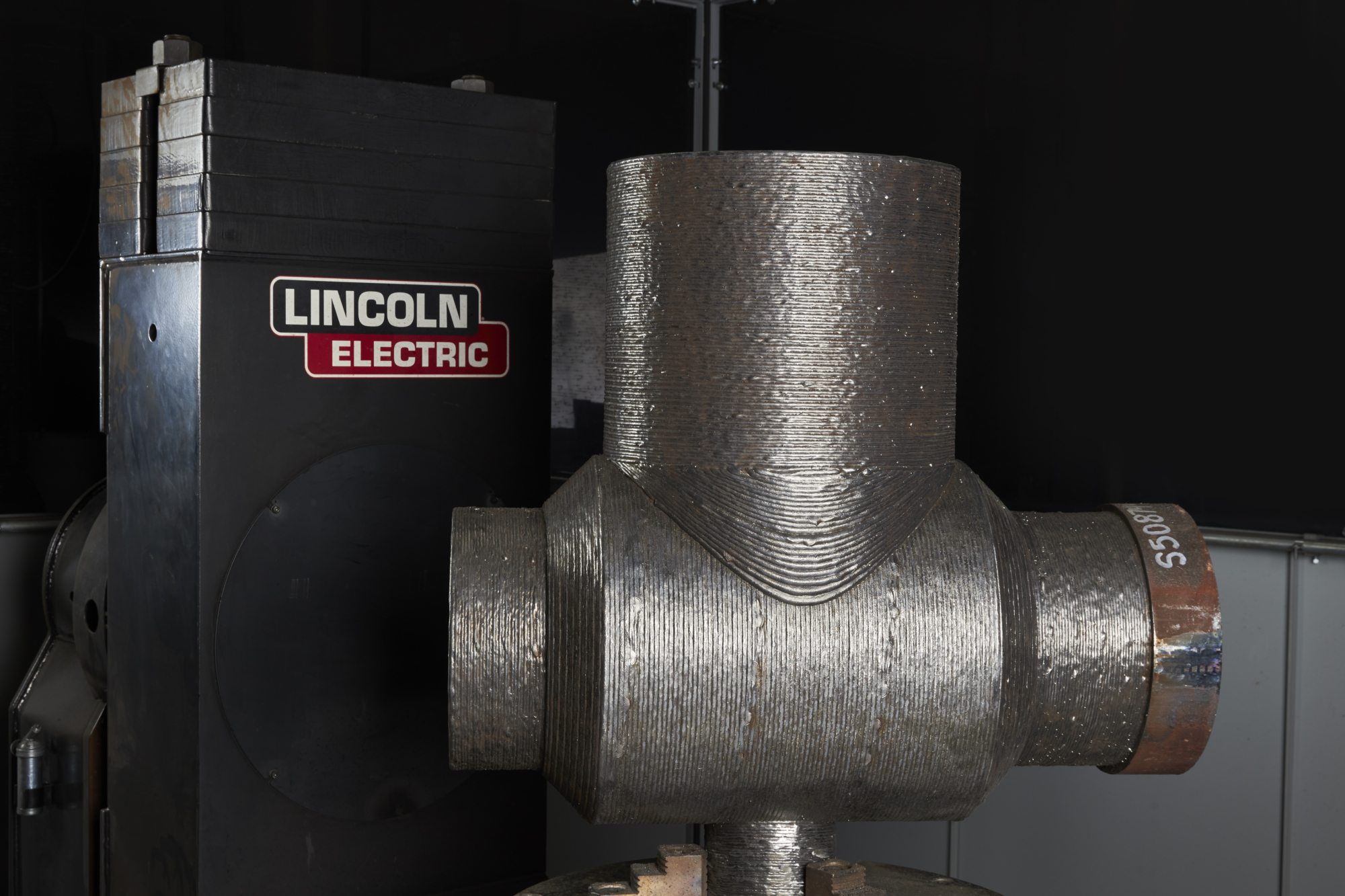

At Fairbanks Morse Defense, we are at the forefront of innovation, leveraging cutting-edge additive manufacturing technology to deliver high-performance solutions for the U.S. Navy. By integrating this advanced technology into our production processes, we’ve revolutionized the way critical components, such as valves, are designed and manufactured, ensuring faster production, enhanced reliability, and unmatched precision.

What is Additive Manufacturing?

Additive manufacturing, commonly known as 3D printing, is a transformative technology that builds components layer by layer from digital designs. This process allows for the creation of complex geometries that are difficult or impossible to achieve with traditional manufacturing methods.

How FMD is Using Additive Manufacturing

Fairbanks Morse Defense has integrated additive manufacturing into the production of valves for the U.S. Navy, delivering significant benefits:

- Rapid Prototyping: We can quickly design, test, and refine valve prototypes, accelerating the development process.

- Custom Solutions: Additive manufacturing enables the creation of highly customized valves tailored to specific naval applications.

- Enhanced Performance: The precision of 3D printing ensures that every valve meets the Navy’s rigorous performance and reliability standards.

- Reduced Lead Times: By streamlining the production process, we can deliver critical components faster, supporting the Navy’s operational readiness.

- Sustainability: Additive manufacturing minimizes material waste, contributing to environmentally responsible practices.

Benefits of Additive Manufacturing

- Improved Fleet Readiness: Faster production and delivery of critical components ensure that naval vessels remain mission-ready.

- Cost Efficiency: By reducing material waste and production time, additive manufacturing lowers overall costs without compromising quality.

- Design Flexibility: Complex valve designs can be produced with ease, enabling innovative solutions for challenging applications.

- Enhanced Durability: Additive manufacturing allows for the use of advanced materials that improve the longevity and performance of components.

Need Assistance? We’re Here to Help.

Contact us for product information, request a quote, service support, or any questions. Our team is ready to provide solutions tailored to your needs.