Robotics

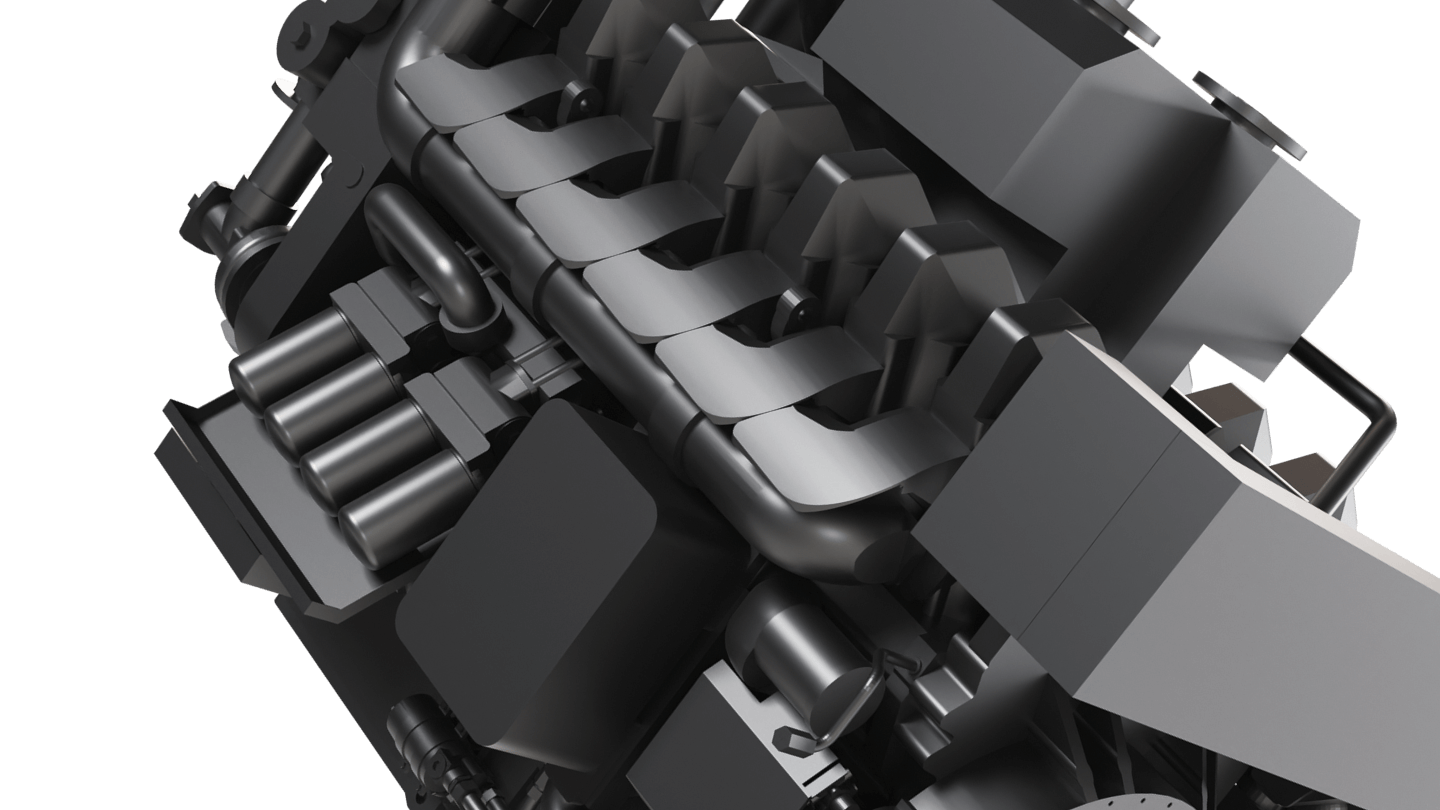

Revolutionizing Crankline Repairs with Robotic Welding

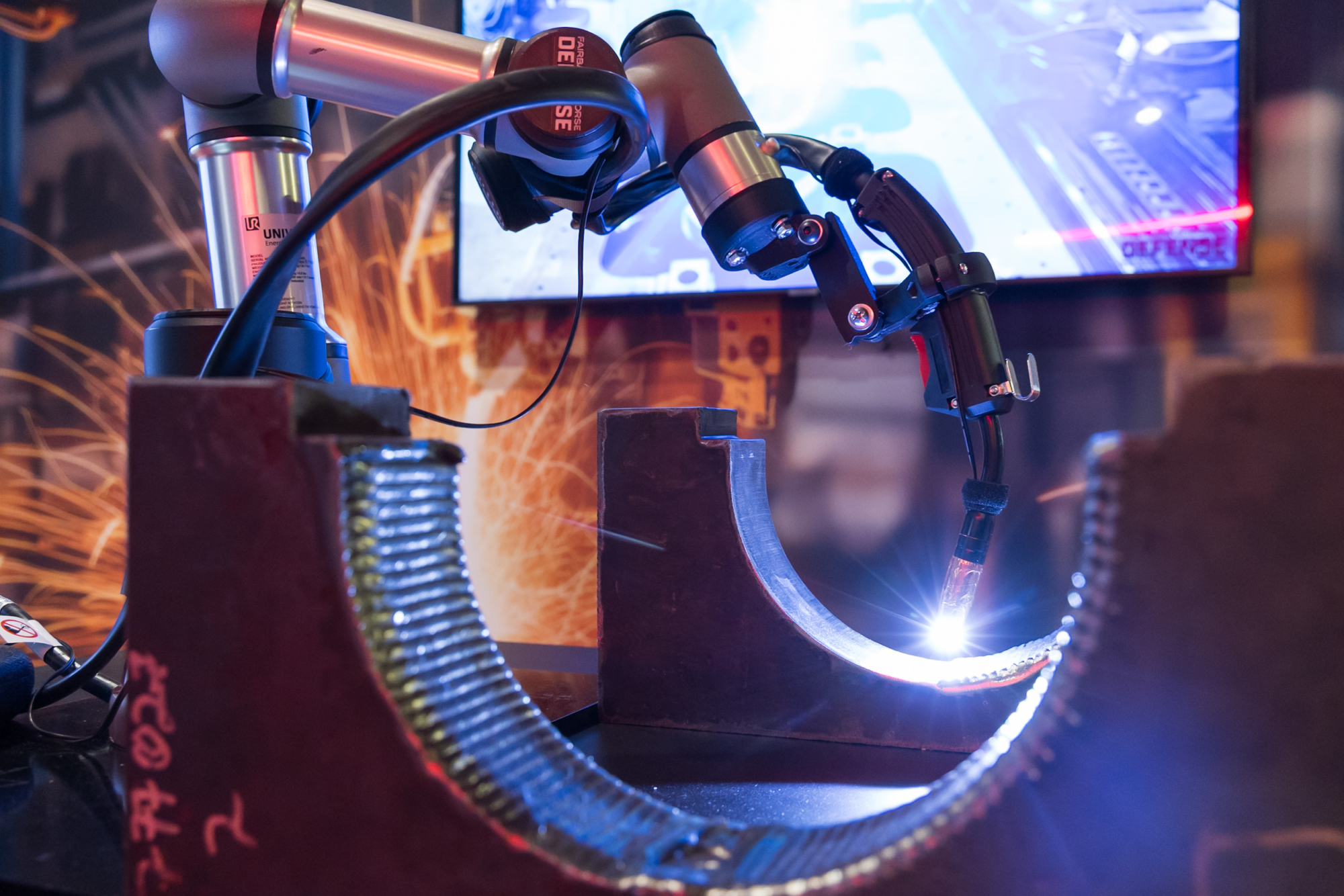

At Fairbanks Morse Defense, innovation drives everything we do. By integrating state-of-the-art robotic welding systems, we’ve transformed the welding process to deliver unmatched precision, efficiency, and reliability. Our approach combines the speed and consistency of robotic technology with the expertise of skilled welders, creating a powerful synergy that sets a new standard in welding excellence.

FMD Robotic Welding Solution

Our robotic welding system is designed to address traditional welding challenges by automating and optimizing the product rebuild process. Key features include:

- In-Process NDT (Non-Destructive Testing): Real-time weld quality monitoring using vision and sensor data eliminates the need for extensive post-weld inspections.

- Track-Based Precision: The system enables precise passes over block saddles, building up material for machining—ideal for submarine and LSD OP engines.

Key Features of Robotic Welding

Benefits of Robotic Welding

Aligned with Submarine Modernization

This robotic welding initiative supports submarine modernization efforts and leverages advancements in commercial CPBPT welding technology. By partnering with additive manufacturing vendors, we’re driving innovation and ensuring our solutions meet the Navy’s rigorous standards.

Proven Success

Our robotic welding system has already demonstrated its value in early prototyping and supplier engagement, paving the way for validated Navy use. With its ability to deliver faster, safer, and more consistent repairs, this technology is setting a new standard for overhauls and repairs.

An Ohio Class Submarine Repair Project: Successfully completed an emergent crank line repair with speed and precision, showcasing the system’s reliability in mission-critical operations.

A Los Angeles Class Submarine Repair Project: Reduced crankline repair timeline, saving costs and improving operational readiness.