HEAT RECOVERY EVAPORATORS

Our heat recovery evaporators utilize waste heat to make high quality potable water from seawater, brackish water or contaminated feed water sources.

We have two series of heat recovery evaporators:

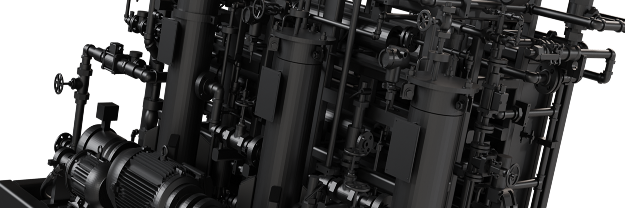

HJ Series

The HJ Series is made of five models, with fresh water capacities ranging from 192 to 3,000 gallons per day.

- Perfect for pleasure boats or small work boats, yachts, cruisers, tug boats, fishing boats, survey vessels, offshore drilling and production platforms, offshore supply vessels, USCG and USN vessels, and many other applications.

- Utilizes waste heat, reducing operating costs since little new energy generation is needed.

- Environmentally friendly since energy is conserved and there are no membranes or filters to replace or dispose of.

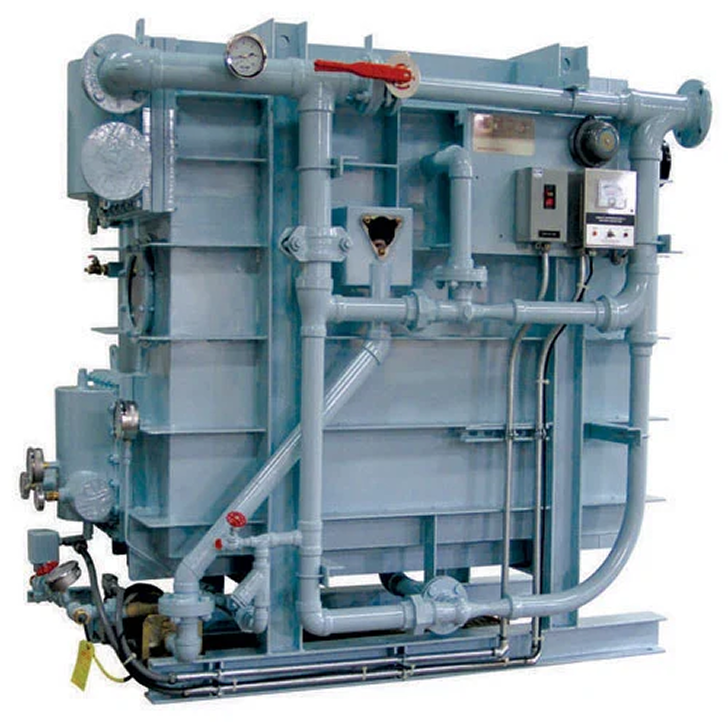

TCF Series

The TCF Series is made up of five models, with fresh water capacities ranging from 3,700 to 15,000 gallons per day.

- Perfect for larger cruisers, tugs, fishing boats, survey vessels, and offshore production platforms.

- Utilizes waste heat, reducing operating costs since little new energy generation is needed.

- Thermo circulation design minimizes scaling and lowers maintenance costs.

- Environmentally friendly since energy is conserved and there are no membranes or filters to replace or dispose of.

MAXIM STANDARD EVAPORATOR DATA CHARTS

Imperial

| Maxim Model No. | Fresh Water Capacity2 GPD | Eng. Load (Dev. BHP) | Gen. Load (Dev. KW) | Jacket Water GPH | FT | Heat Input Requirements (BTU/hr) | Sea Water Flow (GPH)3 | Elect. Power Req’d4 (KW/hr) | Net Wt. (lbs) | Approximate Dimensions (inches) LxWxH |

| HJ3C | 192 | 38 | 30 | 390 | 15.5 | 75,000 | 360 | 0.8 | 125 | 20x11x23 |

| HJ10C | 600 | 125 | 93 | 1,200 | 15.0 | 250,000 | 1,140 | 2.9 | 250 | 36x20x26 |

| HJ20C | 1,200 | 250 | 186 | 2,400 | 16.2 | 500,000 | 2,160 | 2.9 | 410 | 43x22x31 |

| HJ30C | 2,000 | 416 | 310 | 4,680 | 25.0 | 832,000 | 4,800 | 6.5 | 625 | 54x24x31 |

| HJ50C | 3,000 | 625 | 466 | 6,000 | 25.0 | 1,250,000 | 5,400 | 6.5 | 970 | 52x29x44 |

| TCF 3.7 | 3,700 | 715 | 533 | 6,900 | 30.0 | 1,430,000 | 7,500 | 0.6 | 2,100 | 55x39x65 |

| TCF 5 | 5,000 | 950 | 710 | 9,360 | 30.0 | 1,950,000 | 9,360 | 0.6 | 2,250 | 55x42x65 |

| TCF 7.5 | 7,500 | 1425 | 1065 | 17,400 | 30.0 | 2,900,000 | 14,700 | 1.6 | 2,900 | 82x44x68 |

| TCF 11 | 11,000 | 2100 | 1565 | 20,400 | 30.0 | 4,250,000 | 20,040 | 1.6 | 4,800 | 92x50x68 |

| TCF 15 | 15,000 | 2850 | 2125 | 27,840 | 30.0 | 5,800,000 | 27,600 | 1.6 | 5,600 | 95x65x76 |

Metric

| Maxim Model No. | Fresh Water Capacity MTPD | Eng. Load (Dev. BHP) | Gen. Load (Dev. KW) | Jacket Water m3/HR | FT | Heat Input Requirements (BTU/hr) | Sea Water Flow (m3/HR) | Elect. Power Req’d (KW/hr) | Net Wt. (kg) | Approximate Dimensions (millimeters) LxWxH |

| HJ3C | 0.73 | 38 | 30 | 1.48 | 15.5 | 75,000 | 1.36 | 0.8 | 57 | 508x279x584 |

| HJ10C | 2.27 | 125 | 93 | 4.54 | 15.0 | 250,000 | 4.31 | 2.9 | 114 | 914x508x660 |

| HJ20C | 4.54 | 250 | 186 | 9.08 | 16.2 | 500,000 | 8.18 | 2.9 | 186 | 1092x559x787 |

| HJ30C | 7.57 | 416 | 310 | 17.72 | 25.0 | 832,000 | 18.17 | 6.5 | 284 | 1372x610x787 |

| HJ50C | 11.36 | 625 | 466 | 22.71 | 25.0 | 1,250,000 | 20.44 | 6.5 | 441 | 1321x737x1118 |

| TCF 3.7 | 14.00 | 715 | 533 | 26.12 | 30.0 | 1,430,000 | 28.39 | 0.6 | 955 | 1397x991x1651 |

| TCF 5 | 18.90 | 950 | 710 | 35.43 | 30.0 | 1,950,000 | 35.43 | 0.6 | 1,023 | 1397x1067x1651 |

| TCF 7.5 | 28.40 | 1425 | 1065 | 65.87 | 30.0 | 2,900,000 | 55.64 | 1.6 | 1,318 | 2083x1118x1727 |

| TCF 11 | 41.60 | 2100 | 1565 | 77.22 | 30.0 | 4,250,000 | 75.85 | 1.6 | 2,182 | 2337x1270x1727 |

| TCF 15 | 56.80 | 2850 | 2125 | 105.39 | 30.0 | 5,800,000 | 104.47 | 1.6 | 2,545 | 2413x1651x1930 |

Above data is for jacket water operation only. Consult factory for data pertaining to steam operation.

2 Capacities are based on 185ºF / 89ºC engine jacket water and 85ºF / 24ºC sea water. Except: model HJ3C is based on 70ºF / 21.1ºC sea water).

3 TCF units do not include sea water pump.

4 Power includes a distillate pump and feedwater pump for the HJ models. Power is the distillate pump only for TCF models.

Represents single stage/single effect design. Additional output or higher thermal economy can be accomplished using multi-effect/multi-stage design.

FAQs

When comparing one of our units to an RO unit of similar high quality, the upfront capital costs are comparable. The same is true when comparing a Maxim evaporator to waste heat units offered by other manufacturers. When considering long term economics, significantly longer equipment life and low operating costs yield an excellent return-on-investment.

The installation of an evaporator is similar to that of an RO unit. Both systems require connections to seawater feed, brine reject overboard and a connection to a fresh water holding tank. The only additional connection required by an evaporator is to the hot water loop coming from the engine and prior to the radiator or keel cooler. This connection is simple to perform and Maxim provides the technical support to assure it is done properly.

Maintenance involves prevention or removal of scale formation on the seawater heater tubes and the evaporator boiling chamber.

Scale prevention includes the use of a chemical feed system with an effective scale prevention solution. Very small doses of the solution are introduced into the incoming feed water on a continuous basis to prevent minerals dissolved in the feed water from forming on the tube surfaces. Maxim offers MAX-Defense.

Scale removal is another method of maintenance. Scale can be removed periodically using a low pH cleaner. This is accomplished while the system is still in operation and only requires about 15 minutes. Cleaning frequency is dependent on the amount of time the evaporator is in operation and the chemistry of the incoming feed water.

Maxim equipment is designed to minimize scale formation to keep maintenance time and costs to a minimum. Scale is minimized by boiling water at low temperatures under a vacuum along with the turbulent flow of water at critical points in the evaporator.

Heat recovery evaporators operate consistently across all types of feed water and can handle wide ranges of feed water temperatures. Evaporators can function well in river water, brackish bay water, or seawater and yield the same high quality water. The water quality is consistently good even when feed water contains silt, sand, oil and other contaminants found in coastal waters. The feed water pretreatment consists of only a screen strainer.

Heat recovery evaporation is the most energy efficient desalination technology when waste heat is available. Waste heat from engine jacket water, exhuast gas, or other heat sources is utilized which provides the bulk of the energy requirement and reduces operating costs.

There are no consumables such as filters and membranes required on evaporators which reduces maintenance time and costs. An evaporator operates under low pressure and has few moving parts thus making this system highly reliable.

Water produced is high quality, containing less than 4ppm of total dissolved solids, compared to the water quality produced by an RO unit which contains 200 to 500ppm of total dissolved solids. The water produced by an evaporator is less corrosive and aggressive than that produced by an RO unit.

Heat recovery evaporators also do not require the use of membranes or filters. Membranes and filters foul in the presence of certain types of feed water and do not react well to changes in the feed water. Evaporators are very effective in all environments from bay water to offshore and all points in between.

A heat recovery evaporator is friendly to the environment. There are no filters or membranes that ultimately end up in landfills. The use of waste heat also reduces carbon emissions.

Fresh water made from sea water tends to have a lower pH and can be aggressive towards metal piping and storage tanks. The reason is that the desalination process liberates carbon dioxide which ends up dissolved in the clean water which lowers pH. The water made with reverse osmosis equipment tends to be more acidic since all of the carbon dioxide liberated easily passes through the RO membrane and ends up in the fresh water. In an evaporator, a large portion of the carbon dioxide is removed along with other non condensable gases because of the vacuum that is created. With less carbon dioxide in the water, fresh water made by an evaporator is less aggressive toward metal piping and storage tanks.

Parts & Service

Fairbanks Morse Defense offers an extensive portfolio of services to optimize performance, ensure reliability, and extend the life of your fleet – from the day its commissioned and for the many years that follow. Learn more about what our custom solutions can do for you.

Commercial Solutions

In addition to the defense industry, Fairbanks Morse Defense also works with the commercial industry. Our commercial customers can include municipal and nuclear power plants, hospitals, universities, and international stationary power applications.

Ready to get started?

Contact us today to request a quote or get more information on any of our solutions and services.