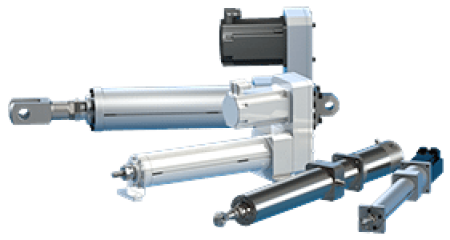

Victory A-Series Ram-Style Electromechanical Actuators

-

BUILT FOR PERFORMANCE AND VERSATILITY

Even small variations can make a big difference to the performance and versatility of electromechanical actuators. Because requirements differ, Victory A-Series Actuators can be configured to meet specific applications, including those in harsh environments. Hunt’s extensive design and engineering experience makes all the difference to provide equipment builders and end users an economical, heavy-duty, clean, efficient and precise alternative to hydraulic and pneumatic actuators.

The Victory A-Series allows the user to maintain better thrust and speed control with low maintenance needs. When combined with servo motors and controls, the Victory A-Series actuators provide nearly infinite programmability, reduced set-up times, and better control over:

- Thrust

- Speed

- Acceleration/Deceleration

- Force

- PositionThese electromechanical actuators are perfect for moving loads that pivot, for applying force to an externally supported load, and for environments where there is a high concentration of airborne contaminants. The tubular design increases the sealing and connection strength between the outer housing components; and with unparalleled flexibility in housing material selection and in mounting features, these actuators are adaptable to almost any environment and application.

Screw versions and options include ballscrew assemblies for high-duty cycle requirements, ACME/trapezoidal lead screws for lighter duty cycles, and planetary rollerscrews for increased load and life requirements.

VICTORY A-SERIES BENEFITS

Hunt’s engineers designed the Victory A-Series with users in mind. Some benefits of this product line include:

- Flexibility for use with ball screws, roller screws or ACME screws to suit unique load, speed, and duty cycle requirements

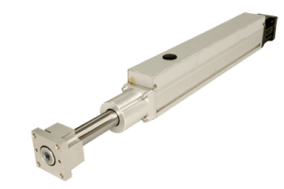

- Internal anti-rotation design of the rod to prevent the load or tooling from rotating as it translates

- Long ram guide bearing to provide smooth extension and retraction of the rod

- Wiper and seal protection against the ingress of liquids and particles

- Standard ISO rod-end attachments available for affordable and industry standard connection to the load

- Chrome-plated inner ram (stainless steel for food grade units) to increase corrosion resistance

- Screw support bushing reduces whipping and vibration of the screw to increase dynamic performance and reduce noise

- Bumpers protect the internal components from minor accidental over-travel mishaps

- High-capacity angular contact bearings ensure long-life and high thrust capacity

- High-strength timing belt provides long-life and precise transfer of motion on parallel motor mount options

- Multiple mounting options for pivoting and rigidly mounted applications

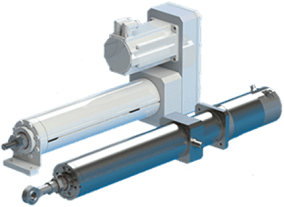

- Parallel motor mounting reduces overall length and allows for rear clevis mounting

- Stainless steel primary rod-ends on all variations for durability

- Rod-end mounted central lube port simplifies maintenance by allowing re-lubrication of the entire unit at any stroke position

- Aluminum exterior construction reduces system weight and cost

- Adjustable position sensors provide over-travel protection and indication of position; dual T-slots allow for positioning at any location along entire stroke of the unit- Motor adaption flexibility allows the use of any reasonably-sized motorKEY FEATURES

- Designed to handle appreciable loads, speeds, and duties

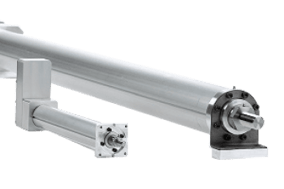

- Standard stroke lengths up to 1,524mm (60 inches) available in 1mm increments

- Standard capable thrust loads up to 11,865 lb-f

- Modular frame, mounting, rod-end, and drive execution designs

- Standard internal anti-rotation of the thrust rod Internal end-of-stroke shock absorbers

- Corrosion resistant material construction

- Available food-grade and full stainless steel designs

- Easily and infinitely adjustable proximity limit sensors

- Flexible adaptation for most motor selections

- Capable of being implemented in any orientation Made in the U.S.