Brand: Hunt Valve

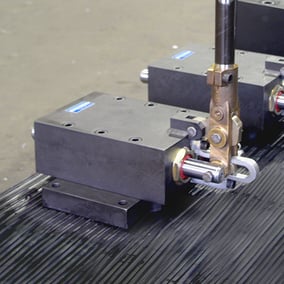

Hunt Valve’s new Mega-Flo C Descale Valves are the longest lasting plunger-style descale valves available.

This ultra-durable plunger-style descale valve saves customers 33% on the total cost of ownership over competitors’ poppet style valves. The savings is based on the initial purchase price and maintenance requirements over the first three years of service, then a 50% reduction in maintenance costs thereafter.

Why Hollow Plunger Technology delivers better durability

Zero Leakage and extended durability:

- Since the UHMW plunger seals create a zero leakage seal, internal component damage from water jetting is eliminated.

- Since the UHMW plunger seals are only directly exposed to the high velocity water flow for 1-2 seconds per shift, wear is minimized.

- Since the UHMW plunger seals are pushed away from the surface of the plunger when shifting the valve, wear is minimized resulting in longer service life and improved contamination tolerance.

Product Features:

- State-of-the-art valve based on Hunt’s proven core plunger technology.

- Advanced materials used in Hunt’s proven integral pressure breakdown design.

- Forged housing designs are treated for corrosion and wear protection to extend the service life of the housing.

- Stainless Steel Housing Liner can be replaced in the field.

- Upgraded cylinder design for less corrosion, wear and friction due to the following:

Nitrocarburized piston rod and tie-rods.

Low friction urethane piston and rod seals.

60 RC hard anodized cylinder bore.

- Low-turbulence flow plunger design.

- Plunger contained in the pressure vessel for safety.

- Staggered flow slots provide gradual acceleration and deceleration of flow during plunger shifting to prevent water hammer.

- Proximity switch or Transducer options for position feedback.

- Isolated air actuator, kept away from the high-pressure fluid.

- Anti-extrusion seals without grease requirements.

- Seal is pushed away from the plunger by the fluid pressure during shifting to prolong life.

- Sealing surface is NOT exposed to the water flow path when valve is open or closed.

Mega-Flo Cartridge-Style Plunger Assembly

Extend the life of your existing valve installation by replacing your old-style cartridge. The Mega-Flo C cartridge assembly is a drop-in fit to the existing Mega-Flo A or B installation for easy field upgrade capability. It offers the benefits of the Mega-Flo C enhancements without having to replace the entire valve system. The cartridge is a 40% cost savings versus purchasing a complete new valve.

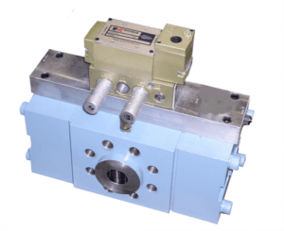

Electromechanical Actuator for Precision Control

Do you have cooling issues with your strip from continuous header pre-fill flow? An electromechanical actuator shifts the plunge from the pre-fill flow position to the full off position to reduce this problem. The new linear actuator design provides precision control.

Besides solving your cooling issues, this actuator:

- Provides the necessary prefill to prevent water hammer and resulting header damage.

- Eliminates the maintenance and reliability concerns of operating an external high-pressure solenoid-operated prefill control valve.

- Relieves safety, maintenance and reliability issues of operating a low-pressure prefill system.

- Offers flexibility to shut off the prefill flow when not required, thus providing increased flow and pressure available for descaling to the system or a significant energy cost savings if one pump can be shut-down by eliminating all of the continuous prefill lines in the system